A carbide insert identification chart PDF is a vital resource for understanding the complex coding systems of these essential cutting tools, detailing shapes, sizes, grades, and chipbreaker geometries.

Overview of Carbide Inserts

Carbide inserts are precision-engineered cutting tools used in machining operations, made from tungsten carbide and other materials for exceptional hardness and wear resistance. They are designed for high-performance cutting in various materials, including steel, aluminum, and high-temperature alloys. These inserts are indexable, meaning they can be rotated to expose new cutting edges, extending tool life. The carbide insert identification chart PDF provides a standardized system to decode their shapes, sizes, grades, and chipbreaker geometries, ensuring proper selection and application. Understanding these inserts is crucial for optimizing machining processes, reducing downtime, and improving overall productivity in manufacturing environments.

Importance of Proper Insert Identification

Proper identification of carbide inserts is critical for ensuring optimal tool performance, reducing operational costs, and enhancing machining efficiency. Misidentifying inserts can lead to incorrect tool selection, resulting in poor surface finishes, reduced tool life, and increased downtime. The carbide insert identification chart PDF serves as a reliable guide, helping users decode complex insert codes based on ANSI and ISO standards. Accurate identification ensures compatibility with toolholders, appropriate chipbreaker selection, and correct grade specification for specific materials. This precision minimizes errors, maximizes productivity, and maintains consistent quality in manufacturing processes, making it an essential skill for machinists and engineers.

Structure of the Carbide Insert Identification System

The carbide insert identification system is structured around a standardized coding method that combines letters and numbers to define specific tool attributes. The system typically starts with shape and clearance angle designations, followed by size and tolerance specifications. Additional codes indicate the grade of the carbide and chipbreaker geometry, ensuring compatibility with various machining applications. This structured approach aligns with ANSI and ISO standards, providing a universal language for tool identification. By breaking down each component of the code, users can easily match inserts to their specific needs, ensuring precision and efficiency in tool selection and application across different machining operations.

Understanding the Carbide Insert Identification Chart PDF

The carbide insert identification chart PDF is a comprehensive guide detailing insert shapes, sizes, grades, and chipbreaker geometries, aiding in proper tool selection and application based on ANSI and ISO standards.

Key Components of the Chart

The carbide insert identification chart PDF includes detailed sections on shape and size codes, tolerance specifications, nose radius dimensions, and chipbreaker types. These components are essential for accurately identifying inserts. The chart also provides grade designations, indicating the material suitability for specific machining applications. Additionally, it outlines clearance angles and hole sizes, which are critical for toolholder compatibility. The chart is structured to help users quickly match inserts to their machining needs, ensuring optimal performance and tool life. By understanding these components, machinists can efficiently select the right insert for their operations, reducing downtime and improving productivity.

How to Read the Chart

Reading the carbide insert identification chart PDF involves understanding its structured layout. Start by identifying the shape codes, which are typically letters like C, N, or M. Next, locate the size codes, usually numbers indicating dimensions. The chart also includes tolerance designations, such as G or M, and chipbreaker types, which affect material removal rates. Refer to the dimensional tables for precise measurements. Pay attention to clearance angles and nose radii, as these impact tool performance. Use the chart’s examples, like the CNMG332 insert, to cross-reference codes. Always align the insert code with the chart’s guidelines to ensure accurate identification and proper tool selection.

ANSI and ISO Guidelines for Insert Identification

The carbide insert identification chart PDF adheres to both ANSI and ISO standards, ensuring global compatibility and consistency. These guidelines provide a standardized system for coding insert shapes, sizes, and grades. ANSI focuses on American National Standards, while ISO offers international designations, both ensuring clarity in tool selection. The chart aligns with these standards, detailing codes for shapes, clearance angles, and chipbreakers. By following these guidelines, users can accurately identify inserts for specific materials and operations. This standardization minimizes errors and enhances efficiency in machining processes, making the chart a reliable resource for professionals worldwide. Adherence to these standards ensures precision and interoperability across different manufacturing environments;

Breaking Down the Insert Code

The insert code is systematically structured, with letters and numbers representing specific features. Letters often denote shape and chipbreaker type, while numbers indicate size, tolerance, and other specifications. This standardized approach ensures clarity and consistency, allowing users to decode and select the appropriate insert efficiently for their machining needs.

Letter and Number Designations

In the carbide insert identification system, letters and numbers are used to denote specific features. Letters typically represent the insert’s shape, chipbreaker type, and tolerance, while numbers indicate size, nose radius, and other geometric properties. For example, in the code CNMG332, the letters C, N, and M specify the shape, chipbreaker, and tolerance, respectively. The numbers 33 and 2 denote the size and nose radius. This systematic approach ensures that each insert’s characteristics are clearly defined, making it easier to select the right tool for specific machining applications. Understanding these designations is crucial for efficient and accurate insert identification.

Shape and Size Codes

Shape and size codes are critical in carbide insert identification, providing detailed information about the insert’s geometry. Shape codes, often represented by letters like C, D, or S, indicate the insert’s shape and application. Size codes, typically numerical (e.g., 32 or 43), denote the insert’s dimensions, including length, width, and thickness. These codes are standardized, often based on ISO or ANSI guidelines, ensuring consistency across manufacturers. For example, in the code SEKN1204, the numbers 12 and 04 specify the size and thickness, respectively. Understanding these codes allows for precise tool selection, optimizing machining performance and ensuring compatibility with toolholders. Always refer to the chart for accurate interpretations and measurements.

Grade and Chipbreaker Codes

Grade and chipbreaker codes are essential for determining an insert’s material properties and chip control characteristics. Grade codes, often represented by letters like P, K, or M, indicate the insert’s material and application, such as steel, cast iron, or non-ferrous metals. Chipbreaker codes, typically letters like F, M, or T, specify the chip control features, influencing how chips are formed and ejected during machining. These codes ensure optimal performance by matching the insert’s capabilities to the workpiece material and machining conditions. For example, a P30 grade is suitable for steel, while an F chipbreaker provides aggressive chip control. Referencing the chart ensures accurate selection for improved tool life and machining efficiency.

Turning Inserts Identification

The carbide insert identification chart PDF details turning insert codes, focusing on shape, size, and grade. For example, CNMG332 specifies geometry, tolerance, and application, ensuring proper tool selection.

Shape and Clearance Angle Designations

The carbide insert identification chart PDF categorizes inserts by shape and clearance angles, using specific letter codes. For example, C denotes a round insert, while N indicates a square with a chamfer. The third letter in the code, such as G or M, specifies the tolerance, impacting toolholder compatibility. These designations ensure proper fitment and performance in machining operations. The chart also details clearance angles, which are critical for maintaining tool integrity during cutting. By referencing these codes, users can accurately identify and select inserts tailored to their specific machining needs, optimizing efficiency and tool life. This system is standardized for consistency across applications.

Tolerance and Nose Radius Specifications

Tolerance and nose radius specifications are critical in carbide insert identification, ensuring proper tool performance and part quality. The third letter in the insert code, such as G or M, indicates tolerance, which must match the toolholder for compatibility. The nose radius, often denoted by the fifth character, determines the insert’s cutting edge geometry. A larger radius enhances tool life but may limit sharpness. The chart provides precise measurements, such as inscribed circle (IC) diameters, to guide selection. Accurate identification of these specifications ensures optimal machining results, minimizing wear and maximizing precision. Proper alignment of tolerance and nose radius with the application is essential for achieving desired outcomes.

Example: CNMG332 Insert Breakdown

The CNMG332 insert code is broken down as follows: C denotes a circular shape, N indicates a 90-degree clearance angle, and M specifies a tolerance class. The G represents a double-sided chipbreaker, while 332 refers to the size dimensions. The third letter (M) is critical for toolholder compatibility, ensuring proper fitment. The inscribed circle (IC) size is determined by the insert’s shape and application. This breakdown helps machinists select the right tool for specific tasks, ensuring optimal performance and tool life. Understanding such codes is essential for efficient machining operations and maintaining precision in manufacturing processes. Proper identification prevents errors and enhances productivity.

Milling Inserts Identification

Milling inserts are identified using specific shape, size, and chipbreaker codes, detailed in the carbide insert identification chart PDF, ensuring precise tool selection for milling operations.

Shape and Size Codes for Milling

The carbide insert identification chart PDF provides detailed shape and size codes for milling inserts, ensuring accurate tool selection. Shape codes like S (square), E (triangular), K (rhombic), and N (nose radius) define the insert’s geometry. Size codes, such as 4, 2, or 3, indicate the insert’s dimensions in both fractional inches and metric measurements. These codes align with ANSI and ISO standards, ensuring consistency across manufacturers. By referencing the chart, machinists can quickly identify the appropriate insert for specific milling tasks, optimizing performance and reducing errors. For example, the SEKN insert code specifies a square shape with a nose radius, making it ideal for certain milling applications. This system streamlines tool selection, enhancing efficiency in machining operations.

Chipbreaker and Tolerance Designations

The carbide insert identification chart PDF details chipbreaker and tolerance designations, crucial for optimizing machining performance. Chipbreaker codes, such as A for light cuts and P for roughing, indicate the edge preparation and chip control features. Tolerance codes, like N for standard tolerances and G for ground inserts, specify dimensional accuracy; These designations ensure proper fitment and performance in toolholders. The chart provides clear guidelines for selecting the right chipbreaker and tolerance for specific applications, reducing tool failure and improving surface finish. Understanding these codes is essential for machinists to achieve precise and efficient cutting operations, as outlined in the comprehensive PDF guide.

Example: SEKN Insert Breakdown

The SEKN insert code is a common designation in milling applications. Breaking it down, the S represents the shape, often indicating a square or round insert. The E denotes the clearance angle, ensuring proper tool life. The K specifies the chipbreaker type, designed for efficient chip control. Finally, the N indicates the tolerance, ensuring precise fitment in the toolholder. This breakdown, as detailed in the carbide insert identification chart PDF, helps machinists select the right insert for specific tasks, optimizing performance and reducing downtime. Understanding such codes is crucial for achieving accurate and efficient machining results.

Parting and Grooving Inserts

Parting and grooving inserts are specialized for precise material separation and groove creation. They feature unique codes for specific operations, ensuring optimal performance in various machining applications.

Specific Codes for Parting Inserts

Specific codes for parting inserts are designed to ensure precise material separation and groove creation. These codes, such as DPET or EPTI, detail the insert’s shape, size, grade, and application. The structure typically includes a prefix, shape designation, size, and grade, aligning with ANSI and ISO standards. For example, DPET inserts are optimized for parting operations, while EPTI inserts are used for threading. These codes help machinists select the right tool for specific materials, like steel or aluminum, ensuring optimal performance and tool life. Understanding these codes is essential for efficient and accurate machining processes in various industrial applications.

Grooving Insert Designations

Grooving insert designations are specialized codes that define the geometry and application of tools used for creating grooves and recesses. These codes, often part of the carbide insert identification chart PDF, specify the insert’s shape, size, and grade. For example, designations like DPET or EPTI indicate specific grooving applications, with details on the insert’s nose radius, tolerance, and chipbreaker type. These codes align with ANSI and ISO standards, ensuring compatibility and consistency. By understanding these designations, machinists can select the right insert for precise grooving operations, optimizing tool performance and material removal rates in various machining processes.

Example: DPET Insert Breakdown

The DPET insert code is a prime example of how carbide insert identification charts simplify tool selection. Breaking it down:

– D represents the insert shape, typically indicating a specific geometry for parting or grooving operations.

– P denotes the chipbreaker type, designed to manage chip formation effectively during machining.

– E refers to the carbide grade, ensuring the insert is suitable for the material being machined.

– T specifies the tolerance class, critical for maintaining precision in the machining process.

This systematic breakdown, as detailed in the carbide insert identification chart PDF, ensures machinists can quickly identify and select the right tool for their application, optimizing performance and reducing downtime.

Threading Inserts Identification

Threading inserts are specialized for creating external and internal threads. Designations like EPTI specify thread type, pitch, and grade, ensuring precise thread machining with carbide tools.

Thread Turning Insert Codes

Thread turning insert codes, like EPTI (External Pitch Thread Insert), specify thread type, pitch, and grade. These codes ensure precise thread machining. EPTI denotes external threads, while IPTI is for internal threads. The numeric value indicates pitch in threads per inch or millimeters. Grades are chosen based on material, ensuring optimal performance. ANSI and ISO guidelines standardize these codes, making them universally applicable. Proper code interpretation ensures correct tool selection, maintaining thread quality and minimizing tool changes. This system is crucial for achieving accurate and efficient threading operations in machining. Always refer to the carbide insert identification chart PDF for detailed specifications and examples.

External and Internal Thread Designations

External and internal thread designations in carbide inserts are defined by specific codes. External threads are denoted by E, while internal threads use I. These codes are part of the insert’s designation system, ensuring proper tool selection. The thread pitch, measured in threads per inch (TPI) or millimeters, follows these letters. For example, EPTI specifies an external thread insert with a particular pitch. Internal thread inserts, like IPTI, are used for boring operations. These designations align with ANSI and ISO standards, ensuring compatibility and consistency. Referencing the carbide insert identification chart PDF provides clear guidelines for selecting the correct insert based on thread type and pitch requirements, optimizing machining accuracy and efficiency.

Example: EPTI Insert Breakdown

The EPTI insert code is a prime example of how carbide insert identification charts simplify tool selection; Breaking it down: E stands for External thread, indicating its use for external threading operations. P denotes the Pitch, specifying the thread pitch in threads per inch (TPI) or millimeters. T refers to the Thread Type, such as right-hand or left-hand threads. Finally, I signifies Internal threading compatibility. This systematic breakdown, as detailed in the carbide insert identification chart PDF, ensures precise tool selection for threading applications, enhancing machining accuracy and efficiency. Such examples highlight the chart’s practical value in decoding insert codes for optimal performance.

Using the Carbide Insert Identification Chart PDF

The carbide insert identification chart PDF is a comprehensive guide, detailing insert shapes, sizes, grades, and chipbreaker geometries, ensuring proper selection and application in machining operations.

Step-by-Step Guide to Using the Chart

Start by locating the insert code on the tool or in the catalog. Refer to the chart to match the code letters and numbers with their corresponding designations. Identify the shape, size, grade, and chipbreaker using the provided tables. Cross-reference the tolerance, nose radius, and hole size to ensure compatibility with your toolholder. Use the visual examples, such as the CNMG332 breakdown, to guide your understanding. Consult the ANSI and ISO guidelines for standardized interpretations. Finally, apply the selected insert to your machining operation, ensuring optimal performance and tool life. This systematic approach simplifies insert identification and enhances machining efficiency.

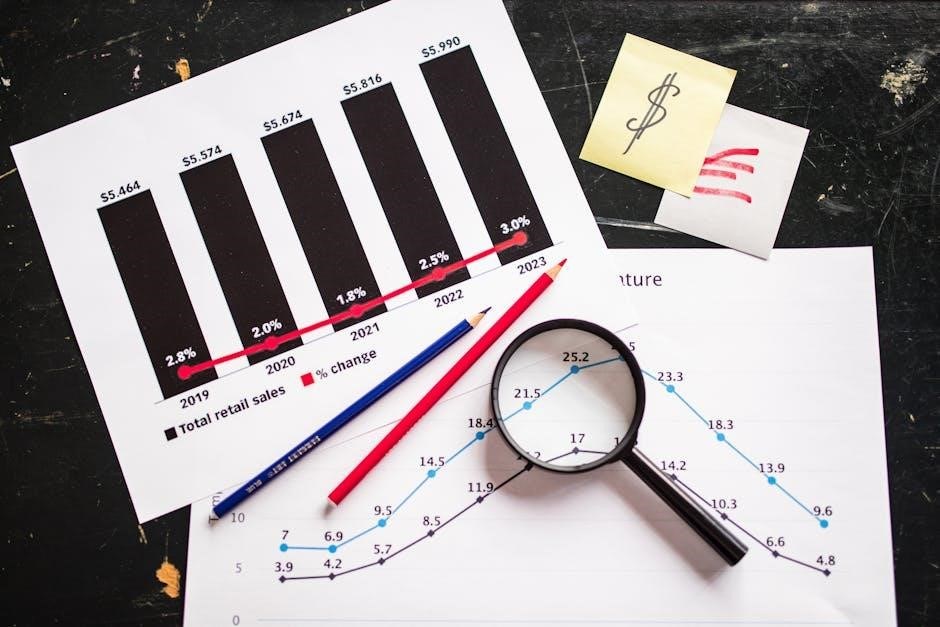

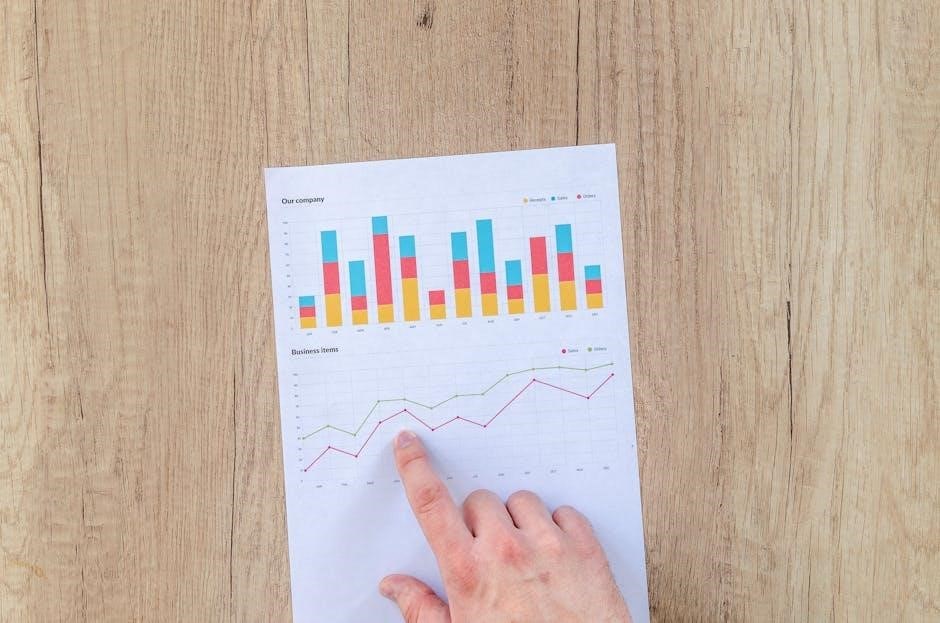

Visual Examples and Case Studies

Visual examples, like the CNMG332 insert breakdown, provide clear illustrations of how codes correspond to insert features. Case studies demonstrate real-world applications, such as optimizing tool selection for specific materials. These examples highlight how understanding the chart improves machining outcomes, reducing errors and enhancing efficiency. By analyzing these practical scenarios, users can better grasp the identification process and apply it effectively in their own operations, ensuring accurate and reliable tool performance across various machining tasks.

Practical Applications in Machining

The carbide insert identification chart PDF is invaluable for machinists, enabling precise tool selection based on material types, such as steel or aluminum. By matching insert codes to specific machining needs, operators optimize performance, ensuring proper chipbreaker geometry and clearance angles. This resource aids in troubleshooting common issues like tool wear or vibration, enhancing overall efficiency. Real-world examples, such as using CNMG inserts for turning or SEKN for milling, demonstrate how the chart streamlines operations. Its practical insights help machinists achieve consistent results, reduce downtime, and improve productivity in various industrial applications.

Troubleshooting and Maintenance

Common issues like insert wear or vibration can be resolved by referencing the chart for proper chipbreaker selection and maintenance tips, ensuring optimal tool performance and longevity.

Common Issues in Insert Identification

Common issues in insert identification include difficulty in measuring tolerance, misinterpreting insert codes, and mismatched shims. Tolerance measurement is challenging due to its precision requirements, often requiring specialized tools. Insert codes can be complex, with letters and numbers representing multiple specifications, leading to confusion. Mismatched shims can cause improper toolholder fitment, affecting performance. Additionally, incorrect chipbreaker selection and misunderstanding ANSI/ISO guidelines are frequent pitfalls. These issues highlight the importance of using a carbide insert identification chart PDF for accurate decoding and proper tool application, ensuring optimal machining results and tool longevity;

Maintenance Tips for Carbide Inserts

Proper maintenance of carbide inserts is crucial for extending their lifespan and ensuring optimal performance. Store inserts in a dry, clean environment to prevent rust and corrosion. Avoid exposing them to extreme temperatures or direct sunlight. Regularly clean inserts with a soft brush or mild solvent to remove debris and coolant residue. Handle inserts with care to avoid chipping or cracking, as carbide is brittle. Use the correct toolholder and shim combinations to prevent misalignment. Refer to the carbide insert identification chart PDF for specific care instructions tailored to your insert type. Proper maintenance ensures consistent cutting performance and reduces tool replacement costs.

Best Practices for Tool Performance

Optimizing carbide insert performance requires adherence to best practices. Always select the correct insert grade and geometry based on the material being machined, as specified in the carbide insert identification chart PDF. Maintain proper toolholder setup and ensure inserts are securely fastened to prevent vibration. Use recommended cutting speeds and feed rates to avoid excessive wear. Apply coolant or lubrication as needed to reduce heat and friction. Regularly inspect inserts for wear or damage and replace them when necessary. Proper chipbreaker selection, as outlined in the chart, helps maintain consistent cutting performance. By following these guidelines, you can maximize tool life and achieve superior machining results.

Resources for Further Learning

Download the carbide insert identification chart PDF for detailed guides, explore online tools, and consult expert forums for comprehensive learning and troubleshooting.

Recommended PDF Guides and Manuals

Download the carbide insert identification chart PDF for a comprehensive guide to understanding insert codes, shapes, and grades. Kennametal’s milling insert identification system and Mitsubishi’s technical guides provide detailed insights. These resources include ANSI and ISO standards, troubleshooting tips, and practical application examples. The chart offers easy-to-read tables for insert dimensions, chipbreaker geometries, and material recommendations. Additional manuals cover safety precautions, calculation formulas, and product guides. Yixin Tools’ PDFs are notable for their competitive pricing and performance. These documents are essential for machinists seeking to enhance their tool selection and machining efficiency. Download these resources to master carbide insert identification and optimization.

Online Tools and Tutorials

Explore online tools and tutorials for mastering carbide insert identification. Kennametal’s interactive guides and Mitsubishi’s technical resources offer detailed insights. Video tutorials, such as the 44-minute and 9-minute sessions, provide step-by-step breakdowns of insert codes. These resources cover ANSI and ISO standards, chipbreaker geometries, and material-specific applications. Interactive charts and dimensional tables help machinists identify inserts accurately. Additionally, forums and expert recommendations provide troubleshooting tips and best practices. These online tools are invaluable for improving machining efficiency and tool selection. Utilize these resources to enhance your understanding of carbide insert identification and stay updated with industry standards and advancements.

Expert Recommendations and Forums

Expert recommendations and forums are invaluable for carbide insert identification. Kennametal’s technical team and Mitsubishi’s resources provide insights into insert codes and applications. Online forums discuss troubleshooting, best practices, and material-specific tips. Experts emphasize understanding ANSI and ISO standards for accurate identification. These platforms also offer advice on maintaining tools and optimizing performance. Engaging with professional communities enhances machining efficiency and ensures proper tool selection. By leveraging expert knowledge, machinists can overcome challenges and stay updated on industry advancements, ensuring high-quality outcomes in their operations.

Mastering carbide insert identification ensures optimal tool performance and efficiency. Utilizing the chart PDF and adhering to ANSI/ISO standards enables precise selection and application, fostering continuous learning and improvement in machining processes.

A carbide insert identification chart PDF is a comprehensive guide detailing shapes, sizes, grades, and chipbreaker geometries. It aligns with ANSI and ISO standards, ensuring accurate tool selection. The chart simplifies understanding complex coding systems, aiding in proper insert application. Key components include shape designations, tolerance specifications, and grade recommendations. Practical examples, like the CNMG332 breakdown, illustrate how to decode insert codes effectively. By following the chart, machinists can optimize tool performance, reduce errors, and improve efficiency. Regular updates and adherence to international standards make it an indispensable resource for both novice and experienced professionals, fostering continuous learning and adaptation in machining environments.

Final Thoughts on Effective Insert Identification

Mastery of the carbide insert identification chart PDF is essential for optimizing tool performance and ensuring precision in machining. By understanding the coding system, machinists can accurately select inserts tailored to specific materials and operations, minimizing errors and enhancing efficiency. The chart’s alignment with ANSI and ISO standards guarantees reliability and consistency across global applications. Regular updates and adherence to international guidelines make it a dynamic resource for continuous learning. Effective insert identification not only improves productivity but also extends tool life, reducing costs and downtime. Embracing this system fosters a culture of precision, innovation, and adaptability in modern machining environments.

Encouragement for Continuous Learning

Continuous learning is key to mastering carbide insert identification. With resources like the carbide insert identification chart PDF, machinists can stay updated on the latest standards and best practices. Exploring guides, tutorials, and expert forums fosters a deeper understanding of insert coding systems. Regularly reviewing ANSI and ISO updates ensures alignment with industry standards. Encourage a culture of lifelong learning to enhance problem-solving skills and adapt to new technologies. By staying informed, professionals can optimize tool performance, reduce downtime, and make informed decisions. Embrace learning as a journey to achieve machining excellence and remain competitive in an ever-evolving field.