This textbook serves as a foundational resource for understanding chemical processes, offering comprehensive coverage of principles, practical applications, and real-world relevance, designed for both students and professionals․

1․1 Overview of the Textbook

The 4th edition of Elementary Principles of Chemical Processes provides a thorough introduction to chemical engineering fundamentals․ It covers core topics such as material and energy balances, thermodynamics, and chemical kinetics, with updated examples and problems․ The textbook is designed for undergraduate students, offering clear explanations and practical applications․ Each chapter builds on previous concepts, ensuring a logical progression of learning․ The inclusion of real-world scenarios and modern technologies makes it relevant to current industrial practices․ Additional resources, such as the solutions manual, support student understanding and problem-solving skills․ This edition emphasizes critical thinking and prepares students for advanced studies and professional challenges․

1;2 Importance of Understanding Chemical Processes

Understanding chemical processes is essential for advancing technology and addressing global challenges․ It forms the backbone of industries like energy, manufacturing, and environmental protection․ By mastering these principles, professionals can optimize production, reduce costs, and improve safety․ Chemical processes also play a critical role in developing sustainable solutions, such as renewable energy and waste reduction․ This knowledge enables innovation in fields like medicine, agriculture, and materials science․ Furthermore, it equips individuals to tackle complex problems, ensuring efficient resource utilization and minimizing environmental impact․ The ability to analyze and design chemical processes is vital for meeting the demands of a rapidly evolving world․

1․3 Structure of the 4th Edition

The 4th edition is organized into seven main sections, each focusing on distinct aspects of chemical processes․ It begins with foundational principles, progressing to core concepts like material and energy balances, thermodynamics, and chemical kinetics․ The textbook then delves into design and analysis of chemical processes, including reactor design, separation processes, and process optimization․ Modern applications and emerging technologies are explored, emphasizing industrial, environmental, and innovative advancements․ The edition concludes with a comprehensive solutions manual, offering detailed explanations and practice problems to reinforce learning․ This structured approach ensures a logical flow, making it easier for students to build a strong understanding of chemical processes from basics to advanced applications․

Core Concepts in Chemical Processes

The core concepts in chemical processes are fundamental principles that underpin the understanding and analysis of various chemical engineering aspects, essential for problem-solving and design․

2․1 Material Balances

Material balances are a fundamental concept in chemical engineering, focusing on the conservation of mass within a system․ They involve tracking the flow of materials into and out of a process, ensuring that the mass entering equals the mass exiting plus any accumulation․ This principle is crucial for designing and analyzing chemical processes, as it allows engineers to determine unknown quantities, optimize operations, and troubleshoot inefficiencies․ Material balances can be applied to entire processes or specific components, making them a versatile tool in process engineering․ They form the basis for more complex analyses, such as energy balances and reactor design․

2․2 Energy Balances

Energy balances are a critical tool in chemical engineering, focusing on the conservation of energy within a system․ They account for all forms of energy, including heat, work, and internal energy, to ensure energy entering a process equals the energy exiting plus any accumulation․ This principle is essential for designing and optimizing equipment such as heat exchangers, reactors, and distillation columns․ Energy balances rely on the first law of thermodynamics and are often applied alongside material balances to solve real-world problems․ They help engineers calculate energy requirements, optimize energy use, and reduce operational costs, making them indispensable in process design and analysis․

2;3 Chemical Kinetics

Chemical kinetics examines the rates and mechanisms of chemical reactions, providing insights into how reactants transform into products․ It involves determining rate laws, identifying reaction orders, and understanding the role of catalysts․ Key concepts include activation energy, reaction mechanisms, and the effect of temperature and concentration on reaction rates․ Kinetic data is essential for designing chemical reactors and optimizing process conditions․ By analyzing rate constants and reaction pathways, engineers can predict reaction outcomes and improve process efficiency․ This section emphasizes the practical application of kinetic principles in solving real-world problems, ensuring processes are safe, economical, and environmentally sustainable․

Thermodynamics in Chemical Processes

Thermodynamics in Chemical Processes explores energy transformations, equilibrium, and system properties․ It applies fundamental laws to analyze and optimize chemical systems and processes efficiently․

3․1 Laws of Thermodynamics

The laws of thermodynamics form the cornerstone of understanding energy interactions in chemical systems․ The first law, conservation of energy, states that energy cannot be created or destroyed, only transformed․ The second law introduces entropy, a measure of disorder, emphasizing that spontaneous processes increase total entropy․ The third law defines absolute zero as the point where entropy is minimized․ These principles govern energy exchange, equilibrium, and system behavior, providing a framework to analyze and predict the feasibility and efficiency of chemical processes․ Understanding these laws is essential for applying thermodynamic principles to real-world challenges and optimizing energy utilization in industrial and natural systems․

3․2 Phase Equilibria and Properties

Phase equilibria and properties are critical in understanding how substances behave under varying conditions․ This section explores the equilibrium between different phases, such as liquid-vapor and solid-liquid systems, and how these equilibria are influenced by temperature, pressure, and composition․ Key properties like density, vapor pressure, and enthalpy are discussed, along with methods to measure and predict them․ The role of equations of state and activity coefficients in modeling phase behavior is highlighted․ Practical applications in equipment design, separation processes, and process simulation are emphasized, providing a solid foundation for analyzing and predicting phase equilibria in chemical systems․ This knowledge is essential for efficient process design and optimization․

Chemical Process Design and Analysis

Chemical process design and analysis involve creating efficient, safe, and sustainable systems․ This includes optimizing processes, ensuring safety, and maintaining environmental standards through advanced engineering methods and tools․

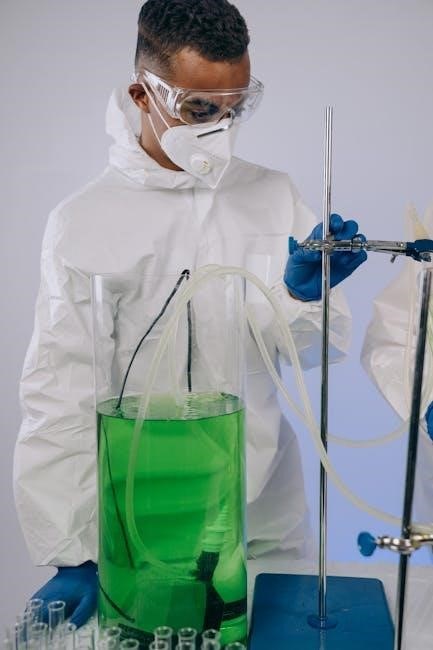

4․1 Design of Chemical Reactors

The design of chemical reactors is a critical aspect of chemical engineering, focusing on optimizing reaction conditions to achieve desired outcomes․ Reactors are engineered to maximize efficiency, safety, and productivity while minimizing costs․ Key considerations include reaction kinetics, thermodynamics, and mass and heat transfer․ Different types of reactors, such as batch, continuous, and catalytic reactors, are designed based on specific process requirements․ Modern reactor design also incorporates computational simulations to predict performance and optimize parameters․ Safety and environmental impact are paramount, ensuring compliance with regulations․ Effective reactor design balances theoretical principles with practical applications, enabling scalable and sustainable chemical processes․

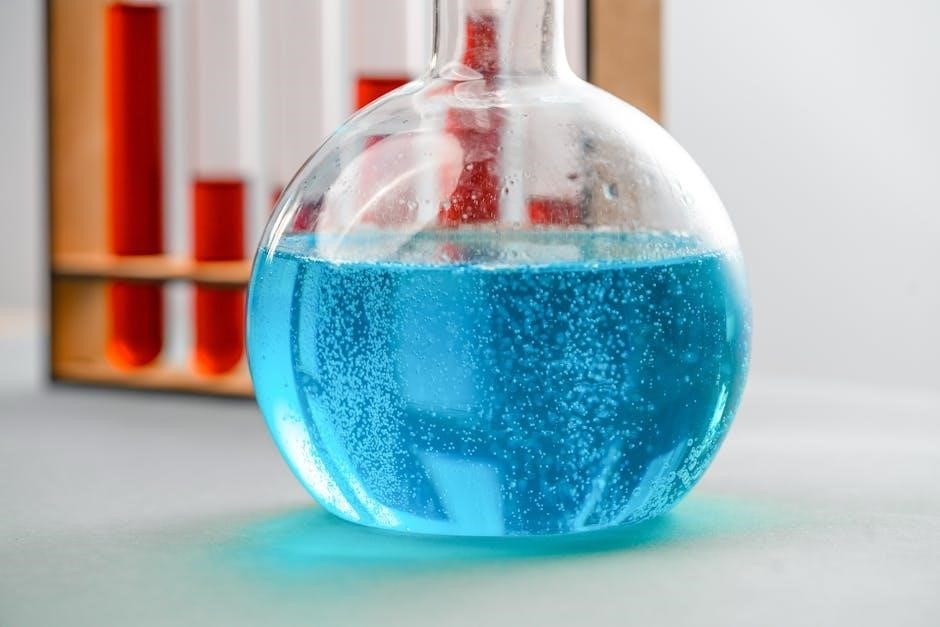

4․2 Separation Processes

Separation processes are essential in chemical engineering to isolate components from mixtures, ensuring purity and efficiency․ Common techniques include distillation, absorption, extraction, and filtration․ These methods rely on differences in physical or chemical properties, such as volatility, solubility, or particle size․ Designing effective separation systems involves understanding mass transfer, phase equilibria, and energy requirements․ Advances in technology have led to more efficient and sustainable separation methods, reducing costs and environmental impact․ Proper selection and optimization of separation processes are critical for achieving desired product quality and meeting industrial standards․ This section provides insights into the principles and applications of various separation technologies․

4․3 Process Optimization

Process optimization is a systematic approach to improving the efficiency, productivity, and sustainability of chemical processes․ It involves identifying and adjusting variables to achieve desired outcomes, such as maximizing yield, minimizing costs, or reducing environmental impact․ Advanced computational methods, including mathematical modeling and simulation tools, are widely used to analyze and predict process behavior․ Optimization strategies often focus on energy consumption, raw material usage, and waste reduction․ By implementing optimized solutions, industries can enhance profitability, comply with regulations, and adopt greener practices․ This section explores the principles, techniques, and applications of process optimization in modern chemical engineering, emphasizing its critical role in industrial success․

Solutions Manual for the 4th Edition

The Solutions Manual provides comprehensive answers to textbook problems, offering detailed explanations and learning aids to enhance understanding and problem-solving skills for students and professionals alike effectively․

5․1 How to Use the Solutions Manual Effectively

To maximize the benefits of the Solutions Manual, start by thoroughly understanding the problem before referring to the solutions․ Compare your approach with the provided answers to identify gaps in your reasoning․ Pay attention to step-by-step explanations, as they highlight key concepts and methodologies․ Focus on understanding the “why” behind each step rather than just the final result․ Use the manual to verify your work and address areas where you struggle․ Regular practice with the problems will enhance your problem-solving skills and prepare you for exams or real-world applications․ Consistent use of the manual will improve your mastery of chemical processes effectively․

5․2 Common Challenges and Solutions

Students often face challenges with complex problem-solving, particularly in material balances and energy calculations․ To overcome these, break problems into smaller, manageable steps and review fundamental concepts regularly․ For difficult topics like chemical kinetics, focus on understanding reaction mechanisms and practice deriving rate laws․ Utilize the Solutions Manual to check your work and identify areas for improvement․ Additionally, leverage online resources, such as video tutorials, to supplement your learning․ Join study groups to discuss challenging problems and gain alternative perspectives․ Consistent practice and timely review of concepts will help build confidence and mastery in solving chemical process problems effectively․

5․3 Practice Problems and Their Solutions

The Solutions Manual provides a wide range of practice problems covering key topics such as material balances, energy calculations, and chemical kinetics․ Each problem is accompanied by detailed, step-by-step solutions that guide students through complex calculations and conceptual understanding․ These exercises are designed to reinforce learning by applying theoretical principles to real-world scenarios․ Additionally, the manual includes hints and explanations to help students identify common errors and improve their problem-solving techniques․ Regular practice with these problems enhances critical thinking and prepares students for advanced topics in chemical engineering․ By mastering these exercises, learners can build a strong foundation for tackling challenges in the field effectively․

Modern Applications of Chemical Processes

Chemical processes are integral to modern industries, driving advancements in sustainable energy, pharmaceuticals, and environmental technologies, ensuring efficient and innovative solutions for global challenges and future developments․

6․1 Industrial Applications

Chemical processes are cornerstone of various industries, driving productivity and innovation․ In manufacturing, they enable the production of petrochemicals, fertilizers, and plastics, ensuring efficient and consistent output․ The pharmaceutical industry relies on chemical synthesis to develop life-saving drugs, while energy sectors utilize processes for refining and biofuel production․ Advanced materials, such as polymers and nanomaterials, are developed through precise chemical control․ These applications underscore the critical role of chemical engineering in meeting global demands, fostering sustainability, and advancing technological progress․ By optimizing these processes, industries achieve higher performance, reduced costs, and improved environmental outcomes, ensuring long-term viability and innovation․

6․2 Environmental Considerations

Chemical processes play a pivotal role in addressing environmental challenges, emphasizing sustainability and eco-friendly practices․ Modern techniques focus on minimizing waste, reducing emissions, and optimizing resource utilization to mitigate ecological impact․ The integration of renewable energy sources and green chemistry principles helps curb pollution and promotes cleaner production methods․ Industries are adopting stricter regulations and advanced technologies to ensure compliance with environmental standards․ Additionally, the development of biodegradable materials and efficient recycling processes contributes to a circular economy․ By prioritizing environmental stewardship, chemical processes can align with global sustainability goals, fostering a healthier planet for future generations while maintaining industrial productivity and innovation․

6․3 Emerging Technologies

Emerging technologies are revolutionizing chemical processes, offering innovative solutions to traditional challenges․ Advances in artificial intelligence and machine learning enable predictive modeling and process optimization․ Modular and microreactor systems enhance efficiency and scalability, while bio-based technologies promote sustainable production․ Renewable energy integration and carbon capture innovations are transforming industrial practices, reducing environmental impact․ These technologies not only improve productivity but also align with global sustainability goals․ The adoption of automation and digital twins further streamlines operations, ensuring safety and consistency․ As these technologies evolve, they pave the way for groundbreaking applications in various industries, driving the future of chemical engineering and process development․

This textbook provides a comprehensive understanding of chemical processes, from fundamental principles to practical applications, preparing students and professionals for future advancements and sustainable innovations in the field․

7․1 Summary of Key Concepts

This chapter summarizes the fundamental principles of chemical processes, emphasizing material and energy balances, thermodynamics, kinetics, and process design․ It highlights the importance of these concepts in practical applications, such as reactor design, separation processes, and optimization․ The textbook integrates theoretical knowledge with real-world examples, providing a solid foundation for understanding chemical systems․ Key topics include the laws of thermodynamics, phase equilibria, and the role of kinetics in reaction engineering․ Additionally, the chapter underscores the significance of environmental considerations and emerging technologies in shaping the future of chemical processes․ By mastering these concepts, students and professionals can effectively analyze and design efficient, sustainable chemical systems․

7․2 The Role of Chemical Processes in the Future

Chemical processes will play a pivotal role in shaping a sustainable and technologically advanced future․ As global demands for energy, materials, and environmental solutions grow, innovation in chemical engineering will be essential․ The integration of renewable energy sources, green chemistry, and advanced technologies will drive the development of cleaner, more efficient processes․ Emerging fields like artificial intelligence and machine learning will optimize process design and operation․ Additionally, the creation of novel materials and biotechnological advancements will address pressing challenges such as climate change and resource depletion․ By prioritizing sustainability and innovation, chemical processes will contribute to a healthier planet and improved quality of life for future generations․